Discover the Power of Custom Metal Fabrication

- Understand what custom metal fabrication really means.

- Explore the range of services and technologies available.

- Learn how customer-centric approaches drive success.

Are you looking for a way to bring your unique design ideas to life? Custom metal fabrication is the perfect solution. It involves crafting metal parts and structures that are tailored specifically to your needs, combining precision engineering with artistic creativity. This process is used in countless industries, from construction and automotive to aerospace and medical equipment. Whether you're building something simple or highly complex, custom metal fabrication can provide the right materials and techniques to meet your goals.

In today’s fast-paced world, businesses are constantly seeking ways to stand out. Custom metal fabrication offers a competitive edge by allowing for unique, high-quality components that fit specific requirements. From intricate designs for architectural elements to durable parts for industrial machinery, this service helps turn concepts into real-world products. The flexibility and adaptability of custom metal solutions make them ideal for any project that demands quality, reliability, and innovation.

| Services | Description |

|---|---|

| Laser Cutting Techniques | Using advanced laser technology, precise cuts can be made on various metals, making it ideal for creating detailed patterns and complex shapes. |

| CNC Punching Capabilities | This method allows for efficient production of perforated metal sheets, which are widely used in architectural and decorative applications. |

| Forming and Rolling | Skilled technicians use specialized equipment to bend, shape, and roll metal into customized enclosures, piping, and structural components. |

| Welding Practices | Experienced welders ensure strong, durable joints that meet industry standards, making them essential for structural and mechanical projects. |

| Finishing Touches | Surface treatments like powder coating and polishing enhance both aesthetics and durability, protecting metal from corrosion and wear. |

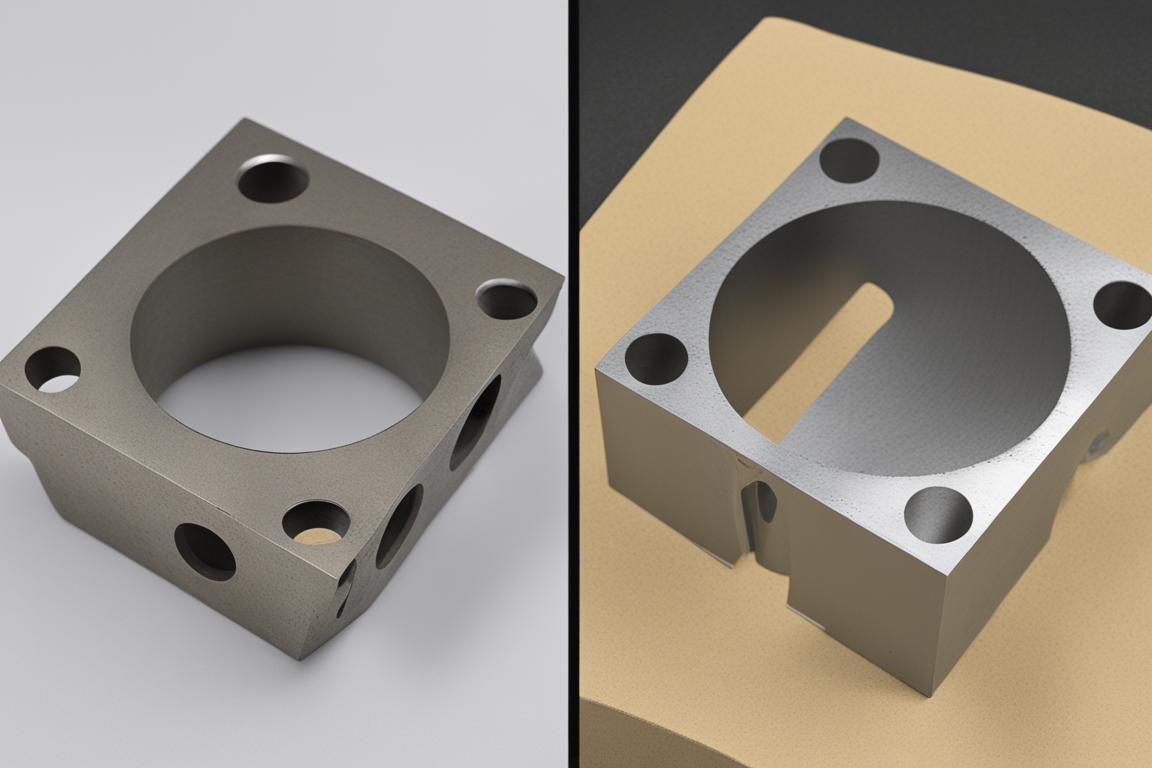

| Machining for Customization | Advanced machining techniques allow for highly accurate and customized parts, suitable for industries such as medical, aerospace, and automotive. |

Why Customer Satisfaction Matters in Metal Fabrication

| Aspects | Description |

|---|---|

| Quality Assurance and Customer Satisfaction | Companies prioritize quality control and client feedback to ensure every project meets the highest standards and exceeds expectations. |

| Tailored Services for Client Needs | Each project is approached uniquely, with close collaboration between fabricators and clients to create solutions that align perfectly with their vision. |

The Key Services That Drive Innovation

Laser Cutting Techniques

Laser cutting is a game-changer in metal fabrication. It allows for incredibly precise cuts on different types of metals, enabling the creation of detailed and complex designs. For instance, a luxury hotel recently used laser-cut panels to add a touch of elegance and uniqueness to its interior spaces, showcasing the versatility of this technique.

CNC Punching Capabilities

CNC punching is an efficient and accurate method for producing perforated metal sheets. These sheets are commonly used in architectural features, soundproofing, and ventilation systems. A recent project involved using CNC-punched metal for a modern office space, proving how effective this technique is for both function and design.

Forming and Rolling Processes

Forming and rolling are essential when it comes to shaping metal into specific forms. These processes are often used to create enclosures, pipes, and even artistic sculptures. A local artist worked with a metal fabrication company to produce a large-scale sculpture, demonstrating how these techniques can blend functionality with artistry.

Welding Practices

Welding is a fundamental part of metal fabrication, ensuring strong and reliable connections. A satisfied client praised a fabrication company for the quality of their welding work, noting how it significantly improved the performance of their industrial machinery.

Finishing Touches and Surface Treatments

After the metal is shaped, finishing touches are applied to enhance both appearance and durability. Powder coating, for example, not only improves the look but also protects against rust and weathering. A furniture manufacturer used this technique to ensure their outdoor products lasted longer and looked better over time.

Machining for Customization

Custom machining allows for the creation of highly precise parts that meet exact specifications. This is especially important in industries like aerospace and medical devices, where even the smallest deviation can have big consequences. A medical device company worked with a fabricator to produce custom parts that met strict regulatory standards.

Putting the Customer First

Customer satisfaction is at the heart of every successful metal fabrication business. Companies understand that each project is unique and require personalized attention. Through consistent communication, transparency, and a commitment to excellence, they build long-term relationships with clients who trust their expertise and reliability.

Quality Assurance and Customer Satisfaction

Many customers have shared positive experiences with custom metal fabrication companies, highlighting the importance of quality and reliability. These stories reinforce the value of working with professionals who care about delivering exceptional results and maintaining strong client relationships.

Tailored Services for Client Needs

Every project starts with understanding the client's goals and challenges. By offering flexible and customized solutions, metal fabrication experts ensure that each product meets the client's expectations while staying within budget and timeline constraints.

In conclusion, custom metal fabrication is more than just a manufacturing process—it's a powerful tool that can elevate your projects across industries. With a wide range of services, skilled craftsmanship, and a focus on customer satisfaction, it's no wonder that businesses continue to rely on this innovative approach. Whether you need intricate designs, durable components, or precision-engineered parts, custom metal fabrication has the expertise and technology to bring your vision to life with unmatched quality and efficiency.

FAQ

Who can benefit from custom metal fabrication services?

Industries such as aerospace, automotive, and electronics benefit greatly.

What is precision sheet metal fabrication?

Precision sheet metal fabrication is the process of cutting, bending, and assembling sheet metal to create custom products.

How can I request a quote for custom metal fabrication?

You can easily request a quote by contacting a reputable fabrication company directly.

What sets precision sheet metal fabrication apart from other methods?

Precision sheet metal fabrication offers high accuracy and intricate details.

How long does a custom metal fabrication project typically take?

The timeline varies based on the complexity of the design and materials used.

But isn't custom metal fabrication expensive?

While it can be a significant investment, the quality and precision of custom metal fabrication often justify the cost.

{"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type": "Question", "name": "Who can benefit from custom metal fabrication services?", "acceptedAnswer": {"@type": "Answer", "text": "Industries such as aerospace, automotive, and electronics benefit greatly."}}, {"@type": "Question", "name": "What is precision sheet metal fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "Precision sheet metal fabrication is the process of cutting, bending, and assembling sheet metal to create custom products."}}, {"@type": "Question", "name": "How can I request a quote for custom metal fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "You can easily request a quote by contacting a reputable fabrication company directly."}}, {"@type": "Question", "name": "What sets precision sheet metal fabrication apart from other methods?", "acceptedAnswer": {"@type": "Answer", "text": "Precision sheet metal fabrication offers high accuracy and intricate details."}}, {"@type": "Question", "name": "How long does a custom metal fabrication project typically take?", "acceptedAnswer": {"@type": "Answer", "text": "The timeline varies based on the complexity of the design and materials used."}}, {"@type": "Question", "name": "But isn't custom metal fabrication expensive?", "acceptedAnswer": {"@type": "Answer", "text": "While it can be a significant investment, the quality and precision of custom metal fabrication often justify the cost."}}]}Feiyiya Inclined Plate Clarifiers Use Gravity & Innovative Engineering

A gravity clarifier is the most economical method of removing solids from liquids, using natural gravity as the source of energy and it is free. A clarifier simply provides a non-turbulent zone where heavier than liquid solids, suspended by turbulence, are given sufficient time to settle to a quiescent surface. The HEI inclined plate clarifiers are compact units with multiple layers of settling area utilizing less than 25% of the floor space required by conventional clarifiers.

Principle of Clarifiers

A particle carried forward by the velocity of the liquid flow must settle at a rate that allows it to reach the bottom before passing through the clarifer. Thus, particles beginning at a point [a" must traverse some route lying between ab and ab` in order to avoid being carried over the outlet.

If V is the horizontal velocity of the liquid, S the solids particle vertical settling velocity, L the length of the settling device, and D its depth, then particles entering at point A will settle to the bottom of the device only if V does not exceed: S(L/D)Since Vmax / S = L / D then, Vmax = S (L / D)

Therefore, the velocity at which a horizontal clarifying device may be operated successfully is directly proportional to its length and inversely proportional to its depth.

This analysis applies to multiple horizontal plate units also. The spacing between plates is usually a few inches as opposed to a depth of several feet in a horizontal tank; therefore, [settling-out" times are dramatically reduced. The flow must be non-turbulent to prevent settled solids from being re-entrained within the moving liquid. Small plate spacing and a large surface area permits laminar flow at higher velocities than large horizontal tanks would allow.

Horizontal clarifying devices become self-flushing if they are inclined at an angle which exceeds the angle of repose of the settled solids. In such cases, flow enters the lower end of the device where settling particles move to the floor eventually sliding back out the entrance. Clear effluent leaves the top of the device.

However, when the device is inclined, the furthest settling particles no longer fall through distance D but some longer distance D`. This new longer settling distance D` is related to D by the relation: D = D` cos Ø.

However, when the device is inclined, the furthest settling particles no longer fall through distance D but some longer distance D`. This new longer settling distance D` is related to D by the relation: D = D` cos Ø.

Theta [Ø" is the angle, the device is inclined to the horizontal plane. Thus settling distance is increased by the factor: 1/cos Ø In the case where Ø = 60º, 1/cos Ø = 2.

The maximum settling distance is twice the distance between the plates. It is apparent then that the lower the angle of inclination, the smaller the settling distance. However, the angle of inclination must exceed the angle of repose of the solids to be separated. The previous equation may be modified to express the cosine of an inclined plate clarifying system as:

Vmax = L / (D / cosØ) (s) = L·cosØ / D (s)

Inclined Plate Clarifiers

A reduction of the required floor space is acquired by diminishing the separation between the horizontal plates to a few inches and stacking the settling surfaces. Inclining the plates to provide self flushing, 45º for heavy particles and 60º for light particles, reduces the available horizontal projected area (effective settling area) by a factor equivalent to the cosine of the angle. The surface area diagram (below) graphically compares the floor space requirements of an HEI inclined plate clarifier with the equivalent horizontal projected settling area.

Settling Rate

The settling rate for a specific solids should be determined by standard laboratory tests. Light particles, such as metal hydroxides, usually require a design parameter of 0.25 – 0.50 gallons per minute per square foot of horizontal projected area. These low density solids require the inclined plates to be set at a 60º angle to induce the particles to slide down the plate. Heavier particles (such as sand that easily flow) will readily slide from plates set at a 45º angle.

Maximum flow rate of an inclined plate clarifier is based on the flow rate per unit of a horizontally projected surface area. Retention time in the clarifier is not a design criteria. However, attaining optimum performance requires the prudent design to recognize several additional, very important factors.

Inclined plate clarifier, Lanmei inclined plate clarifier, Inclined Tube Settler,High-Efficiency Inclined Tube

Wuxi Feiyiya Environmental Protection Technology Co., Ltd. , https://www.feiyya.com