Inspecting 63 Tanks With 2 Drones In 2 Weeks

The Elios drone helped TDBR Inspections revolutionize tank inspections at the 3R-2 rig off the coast of Brazil

Benefits In A Nutshell

|

Speed With just two staff members and the Elios 2 and Elios 3, TDBR was able to inspect 63 tanks in just 14 days. This is a huge leap from traditional methods, which could take months with multiple teams involved. |

Safety Using drones eliminated the need for human entry into confined spaces or working at height. This not only improved safety but also removed the requirement for special permits, making the process more efficient and less risky. |

|

Accuracy The data collected by the Elios 2 and Elios 3 met all the required class standards. The results were shared with the Class Society, confirming the reliability and precision of the drone-based inspection method. |

Efficiency By using drones, the number of people on board the rig was kept within limits. This allowed engineers and workers to focus on core operations rather than spending time on inspections. |

Offshore operations come with unique challenges. Equipment failures or delays in material delivery can lead to costly downtime or even safety hazards. At the same time, every inch of space matters, and there's always a need to balance inspections, maintenance, and operational efficiency. That’s where drone technology makes a real difference.

Customer Needs: Challenging Inspections For An Offshore Rig

The 3R-2, a TLWP-type oil rig located off the coast of Brazil, faced significant inspection challenges. With a maximum crew limit of about 60 people, optimizing personnel was essential. Staff had to be transported by helicopter, so reducing the number of inspectors on-site helped streamline operations without overburdening the platform.

The tanks being inspected are very high, making them difficult to inspect manually

Inspecting large onboard tanks was a major task. It often required several workers using ropes and took days per tank. With the facility operating under strict regulatory standards, thorough and accurate inspections were crucial. The challenge was finding a way to collect reliable data without sending large teams of inspectors for extended periods.

Solution: Using Drone Inspections To Save Time

TDBR Inspections, a leading drone service provider in Brazil, was approached by Raul Martini, a naval engineer from 3R Petroleum, who owns the 3R-2. Their goal was to use the Elios drone for tank inspections and reduce both time and logistical complexity.

The Elios 2 (upper) and Elios 3 (lower) outside the narrow entry for a tank

The Elios 2 (upper) and Elios 3 (lower) outside the narrow entry for a tank

The project aimed to gather visual data on the condition of the tanks, identify defects, and mark areas requiring maintenance. With over 70 tanks on site, the plan was to conduct multiple visits and collect comprehensive data. The key advantage of using the Elios drone was its ability to eliminate the need for special permits and reduce the time spent on each inspection.

Results: Inspecting 63 Tanks In 88 Flights

A team from TDBR Inspections traveled to the 3R-2 to begin Phase 1 of the project. They used the Elios 2 for reconnaissance flights and planned the next steps. A month later, they returned with the Elios 3 to start the actual inspections.

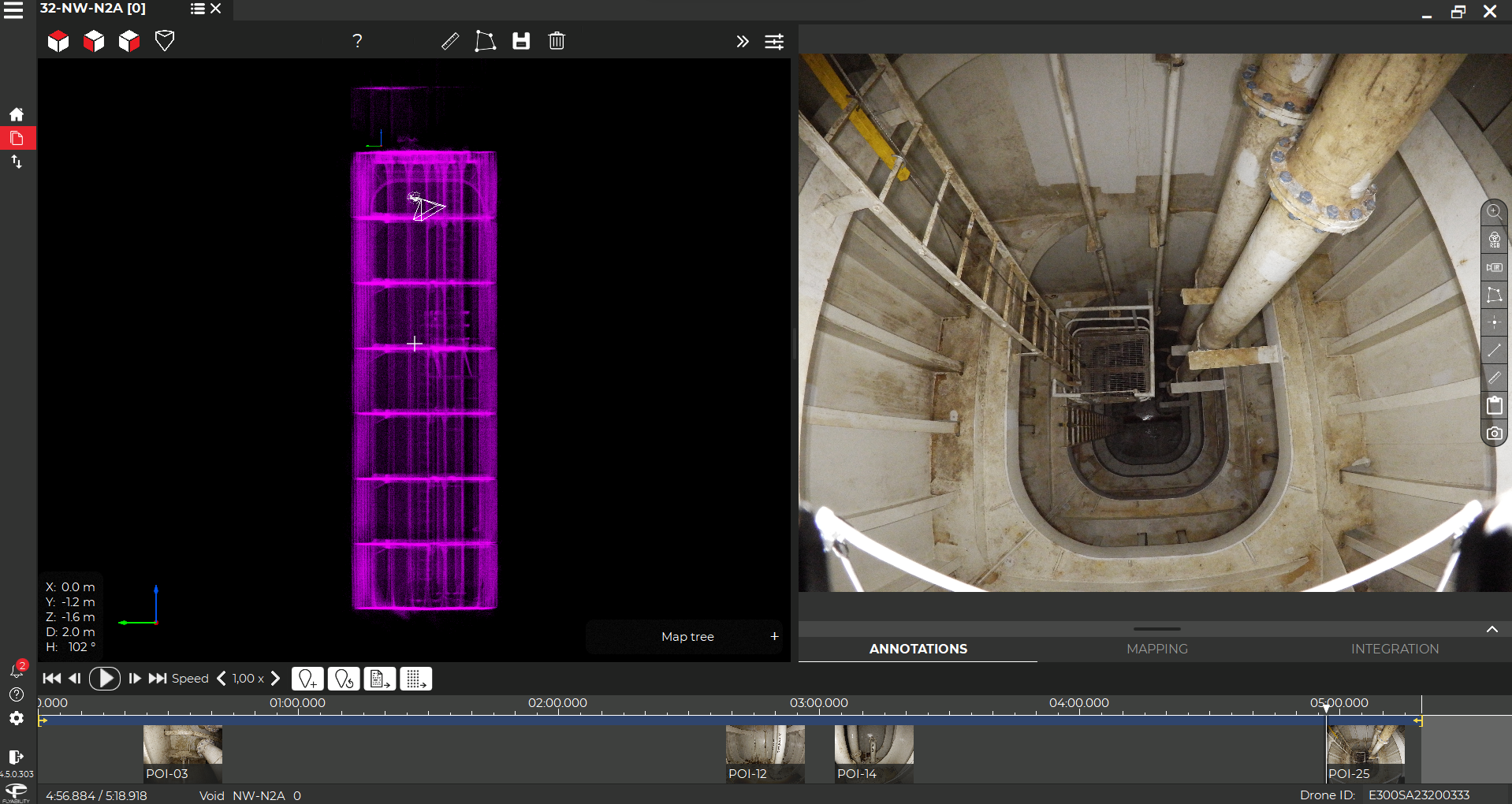

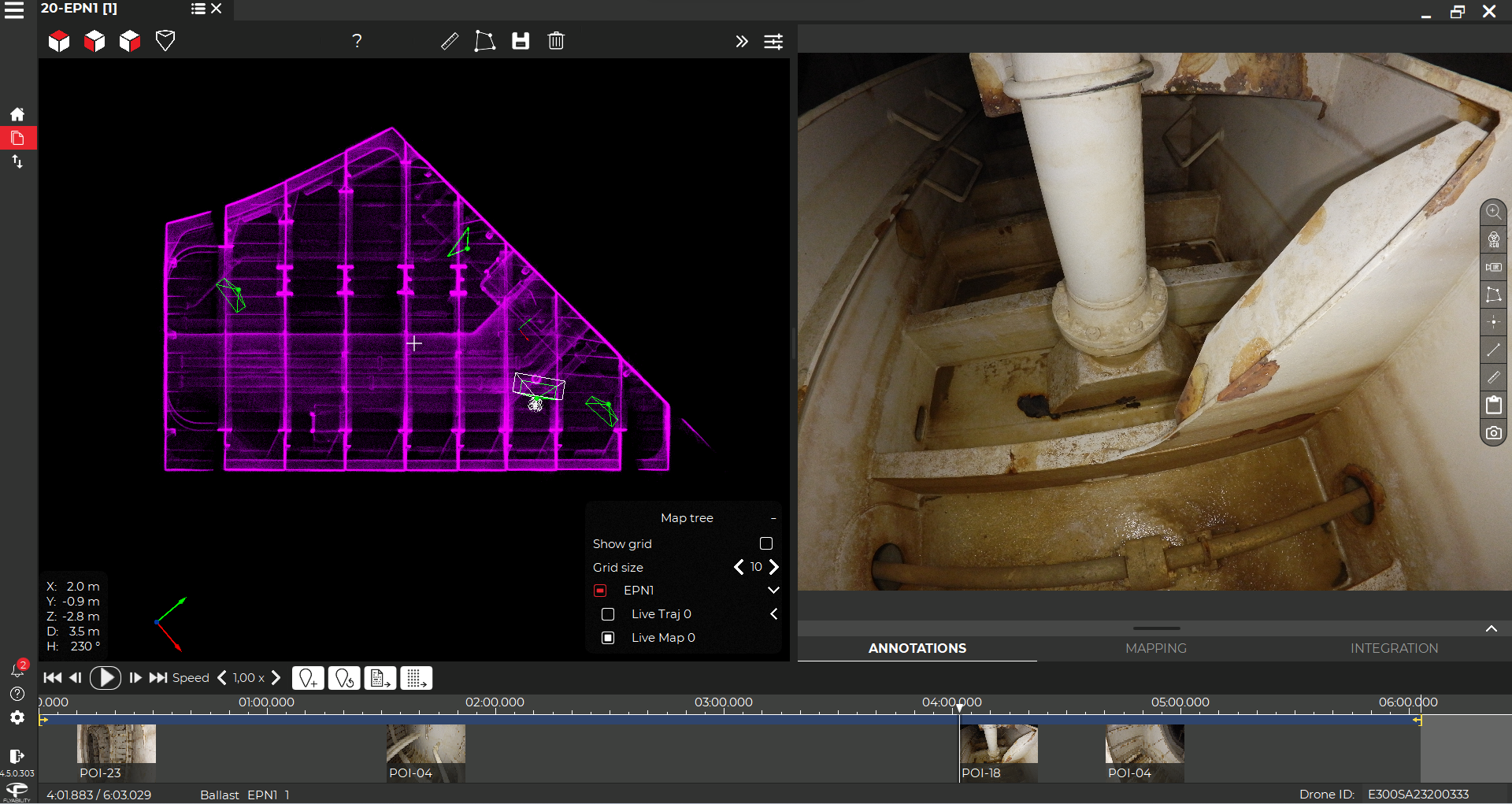

The inside of a ballast tank visualized with the Elios 3

Over the course of 14 days, the team completed 88 flights across 63 tanks. This included over 10 hours of flight time using both the Elios 2 and Elios 3. After the flights, the data was processed using Inspector 4 software. The Elios 3's LiDAR data was used to create 3D models of the tanks, providing detailed insights without the need for human entry.

Conclusion: A Longterm Strategy For Faster Rig Inspections

Inspecting 63 tanks in just 14 days is a remarkable achievement. This equates to over 10 assets per day, a pace that far outperforms traditional methods. On an FSPO, for example, tank inspections typically require 4–5 rope access technicians and can take up to a week. With the Elios 3, it only took two people two days per tank.

TDBR Inspections plans to continue this approach at 3R-2 and other similar sites. The efficiency gained has led to significant cost and time savings, while also optimizing crew movement. More importantly, the Elios drone ensured safety, provided accurate data, and met all regulatory requirements—proving its value in solving a real industry challenge.

Discover more about the Elios 3 and its applications.

Vessel Hardware Parts,Boat Hardware Parts,Vessel Hardware Parts And Accessories,Vessel Hardware Parts Of A Ship

Jiangsu Kinuo Furnace Roller Co., Ltd. , https://www.jskinuoroller.com