Gaskets are essential components in many mechanical systems, serving as a critical barrier to prevent the leakage of gases and liquids. They create a tight seal between two mating surfaces, ensuring that fluids or gases remain contained, even under high pressure or extreme temperatures. Whether you're working on an automotive engine, a plumbing system, or industrial equipment, gaskets play a vital role in maintaining performance and safety. In this guide, we’ll explore what gaskets are, the different types available, how to choose the right one for your needs, and why APG is your go-to partner for all your gasket solutions.

- What Is A Gasket?

- What Are The Types Of Gaskets?

- How To Select The Right Gasket?

- APG: Your Expert With Gaskets!

What is a Gasket?

A gasket is a sealing device designed to fill the gap between two or more mating surfaces. It prevents the escape of gases or liquids by creating a tight, flexible seal. Typically made from materials like rubber, metal, or composite substances, gaskets can adapt to surface irregularities and maintain their integrity under various conditions. Their versatility makes them indispensable in both everyday products and complex industrial applications.

Gaskets are used across numerous industries, from automotive and aerospace to HVAC and manufacturing. They are especially valuable in environments where pressure, temperature, or chemical exposure could compromise the integrity of a connection. Understanding the function and importance of gaskets is the first step in selecting the right one for your project.

What Are the Types of Gaskets?

There are several types of gaskets, each suited to specific applications and environments. Here are some of the most common ones:

-

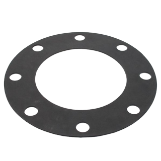

Flat Gaskets: These are simple, thin seals often made from rubber, cork, or metal. They are ideal for flat surfaces and are commonly used in valves, flanges, and pump housings. Flat gaskets are easy to install and replace, making them a popular choice in many industries.

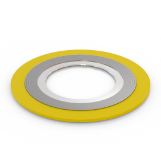

Spiral-Wound Gaskets: These are constructed using alternating layers of metal and non-metallic materials, wound in a spiral pattern. They offer excellent resistance to high pressure and temperature, making them ideal for use in pipe flanges and other demanding applications.

-

Custom Gaskets: When standard gaskets don’t fit, custom gaskets are the solution. Made to precise specifications, they can be tailored to unique shapes, sizes, and materials, ensuring a perfect fit for specialized machinery or equipment.

How to Select the Right Gasket?

Selecting the right gasket involves considering several key factors. First, assess the type of surfaces being sealed—whether they are flat, curved, or irregular. Next, evaluate the operating conditions, such as temperature range, pressure levels, and the type of fluid or gas involved. Different materials perform better under different conditions. For example, rubber gaskets are great for low-pressure applications, while metal gaskets are preferred for high-temperature environments.

It’s also important to think about the longevity and maintenance requirements of the gasket. Some materials degrade faster under certain conditions, so choosing a durable option can save time and money in the long run. Always consult with experts if you’re unsure about which gasket is best suited for your application.

APG: Your Expert with Gaskets!

At APG, we specialize in providing high-quality gaskets and sealing solutions tailored to your specific needs. With years of experience and a deep understanding of materials and applications, our team ensures that every gasket we produce meets the highest standards of performance and reliability.

We offer a wide range of gasket types, including flat, spiral-wound, and custom options, all manufactured using advanced techniques and quality control processes. Whether you need a single gasket or a large-scale production run, we have the expertise and resources to deliver the perfect solution for your project.

Don’t let leaks or poor seals slow you down. Trust APG for dependable gasket solutions that stand up to the toughest conditions. Contact us today and discover the difference of working with real experts!

Â

Â

hbspt.cta._relativeUrls=true;hbspt.cta.load(7315465, 'f2a2d2f0-0bfb-4d25-8045-9f84e0f46567', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(7315465, 'f2a2d2f0-0bfb-4d25-8045-9f84e0f46567', {"useNewLoader":"true","region":"na1"});

Cast Iron,Ductile Cast Iron Bar,Grey Iron And Ductile Iron Casting,Bell And Spigot Ductile Iron Pipe

Shandong Great Steel Co.,Ltd , https://www.great-steel.com