Pressure transmitters play a crucial role in monitoring and managing the pressure of liquids, gases, and fluids across various industrial processes. Known also as pressure transducers, these devices go beyond basic pressure checks, offering versatile solutions for a range of applications. Over time, process industries have discovered innovative ways to utilize these tools. Below, we explore three fascinating applications of pressure measurement devices.

Three Creative Uses of Pressure Transmitters

What are some unexpected ways pressure transmitters can be applied? Here's a look at three intriguing examples that highlight how businesses are thinking outside the box with these instruments.

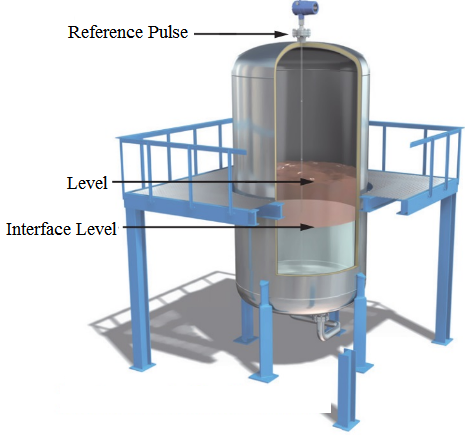

**Level Measurement Applications:** One of the most innovative applications of pressure transmitters is in measuring liquid levels within containers. This works by calculating the pressure exerted on the bottom of the container, which is then used to infer the volume of liquid inside. To ensure accuracy, it's essential to know the exact capacity of the container and the specific gravity of the liquid. Higher gravity liquids exert more pressure per cubic inch, while lower gravity ones have less impact. By factoring in the container size, you can calculate the total pressure and thus determine the level of liquid. Today, specialized pressure transmitters like differential pressure transmitters are widely used for accurate level measurements. These devices provide reliable data when paired with other established techniques for optimal results.

**Flow Measurement:** Pressure transmitters can also serve as alternative flow measurement tools. By placing them on either side of a constricted section of a pipe, they can measure changes in pressure caused by variations in fluid flow. This approach mirrors the functionality of differential pressure flow meters. Although this isn't a direct flow measurement method, it offers a practical solution for those looking to explore alternative measurement techniques.

**Monitoring Filtration Systems:** Pressure transmitters are valuable for monitoring filtration systems. As filters collect debris and contaminants over time, their efficiency decreases, leading to reduced flow rates or even contamination leakage. By installing pressure transmitters downstream of the filtration system, operators can detect gradual pressure drops, signaling the need for maintenance or replacement. This early warning system ensures that the filtration system continues to function effectively without compromising product quality.

While these applications are becoming increasingly common, it’s always wise to consult with a pressure transmitter specialist to identify which models best suit your needs. For further insights into pressure transmitters and their diverse applications, feel free to explore additional resources.

Related Posts:

- What Are the Steps Involved in Calibrating Pressure Gauges?

- All Important Questions on Reconditioned Transmitters Answered

- Is Remanufactured Transmitter a Better Option Than a New One?

- Differential Pressure Transmitters: How Do They Help in Flow Measurements?

- 3 Things That Explain How Often You Should Calibrate Pressure Transducers

- Guidelines for Troubleshooting Pressure Transducers

- Learn How to Calibrate a Pressure Transmitter – II

- Learn How to Calibrate a Pressure Transmitter

- Know Three Interesting Uses of Pressure Transmitters

- The Features and Benefits of Rosemount 1199 Direct Mount Transmitters

- 3 Major Pressure Transmitter Technologies That Made the Device Popular

- An Unconventional Guide to Selecting the Right Pressure Sensor

- Factors to Be Considered While Differentiating $40 and $400 Pressure Transmitters

- Tips to Augment the Performance and Service Life of Pressure Transmitters

- Factors of Consideration When Choosing Pressure Transmitters

- 5 Most Popular Pressure Transmitter Technologies

- Important Calibration Tips for Pressure Sensors

- Tips to Improve the Performance of Pressure Sensors

- Factors to Consider When Choosing a Pressure Transmitter Manifold

- Safety Tips for Differential Pressure Transmitter Operation

- Impact of Shock and Vibration on Pressure Transducers

- Rosemount 3051S vs 3051C Transmitter – What Is Your Choice?

- Rosemount 2088 Vs Rosemount 3051 – A Few Points of Differences Discussed

- What Are Diaphragm Seals and Their Types?

- Difference in Conventional Transmitters and Smart Transmitters

- How to Choose Diaphragm Seals for Your Application?

- How to Select Pressure Transmitter for Your Application?

- Remote Seals: Significance, Working Principle & Applications

- How Do You Calibrate A Flow Transmitter?

- What is Absolute Pressure Transmitter & How Does it Work?

- HART Communication Protocol: Overview, Working Principle, Benefits in Industrial Automation

- Absolute and Gauge Pressure Transmitters - Overview and Working Principle

- Flow Meter vs Flow Transmitter: Know the Difference

- Temperature Transmitter: How to Select The Efficient One for Your Application?

- How Do You Test for 4 to 20mA Signal in a Pressure Transmitter?

- Multivariable Transmitter: What Is It and How Does It Work?

- Pressure Transmitters vs. Pressure Transducers: Learn the Differential Characteristics

- Procedure to Calculate Accuracy of Pressure Transmitter Discussed

- An Ultimate Selection Guide for Flow Transmitters

- The Benefits and Challenges of HVAC System Balancing

- Understanding Pressure Ranges and Units for Fluid System Monitoring

- Understanding the Impact of Pressure Fluctuations on Drying Performance

- Monitoring and Controlling Energy Production in Power Plants

- Common Challenges in Air Flow Measurement and How to Overcome Them

- Pressure Monitoring in Pump Systems: A Comprehensive Guide

- Exploring Density and Viscosity Measurement in Industrial Processes

Carbon Cored Wire,alloy carbon cored wire,Carbon Cored Wire 98%,97% Carbon Cored Wire

ANYANG TIEFA METALLURGY CO.,LTD , https://www.ferroalloytiefa.com