Unlocking New Possibilities Through Waste Heat Recovery in Industries

Every day, countless industrial processes rely on vast amounts of energy to keep operations running smoothly. However, a substantial portion of this energy escapes as waste heat, often ending up unused and released into the environment. This represents a significant missed opportunity. By recovering this wasted heat, industries can enhance their efficiency, reduce costs, and contribute to environmental sustainability. Here’s how waste heat recovery can transform various sectors.

Click to Expand

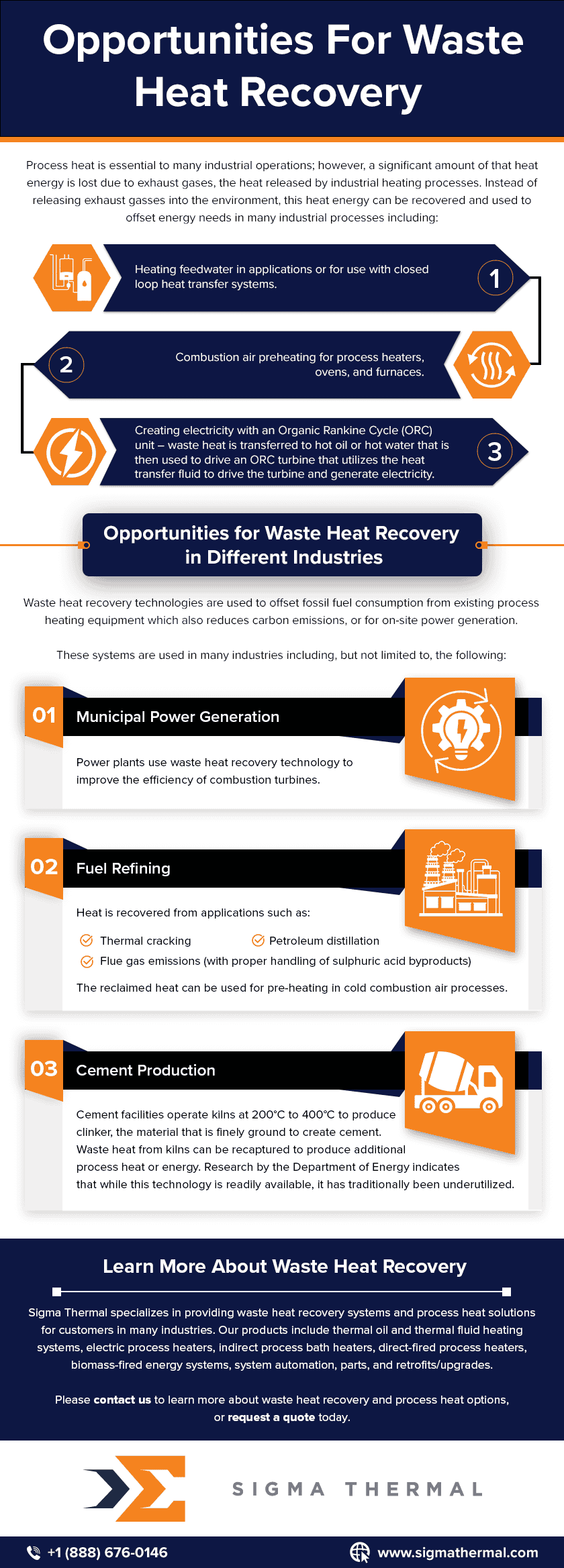

Process heat is vital across industries, yet much of it gets lost through exhaust gases, steam, or cooling processes. Rather than letting this valuable resource go to waste, businesses can harness it for numerous purposes. Recovered heat can be used to preheat feedwater for boilers, warm combustion air for industrial heaters, or even generate electricity using an Organic Rankine Cycle (ORC) unit. In these systems, waste heat transfers to a working fluid—typically hot oil or water—that drives a turbine connected to a generator, thereby creating electricity.

Industry-Specific Applications of Waste Heat Recovery

Waste heat can be categorized into three temperature ranges: high (over 400°C), medium (100–400°C), and low (below 100°C). Depending on the temperature level and specific requirements, different methods of waste heat recovery can be employed. Systems might incorporate components like heat exchangers, condensers, turbines, and generators to maximize energy savings. Let’s explore some real-world examples of how this technology is already making waves across multiple industries.

Municipal Power Generation

Power plants are prime candidates for waste heat recovery. These facilities can leverage advanced heat recovery systems to boost the efficiency of combustion turbines and boilers, ultimately reducing fuel consumption and operational expenses. Additionally, such upgrades help lower greenhouse gas emissions, aligning with global sustainability goals.

Fuel Refining

In fuel refining, waste heat recovery plays a crucial role in optimizing energy use. For instance, heat from processes like thermal cracking and petroleum distillation can be redirected back into the system. This not only cuts down on reliance on external energy sources but also improves overall plant productivity. It’s worth noting that when dealing with flue gases, proper measures must be taken to handle any associated sulfuric acid byproducts safely.

Cement Production

At cement manufacturing sites, kilns operate at extremely high temperatures, producing clinker—the key ingredient in cement production. While this process inherently generates large quantities of waste heat, historically, much of it has gone untapped. Recent studies suggest that implementing effective waste heat recovery strategies could significantly reduce energy demands without compromising output quality.

Food Industry

The food sector presents another fertile ground for waste heat recovery innovations. Low-to-medium-temperature waste heat abounds here, originating from activities such as refrigeration, cooking, and washing procedures. By capturing and repurposing this surplus warmth, manufacturers can achieve cost reductions while maintaining hygiene standards—a win-win situation!

Iron and Steel Industry

Producing iron and steel consumes immense amounts of energy, leading to equally massive volumes of discarded heat. There are myriad opportunities within this field for capturing and reusing excess warmth, whether it comes from cooling zones, blast furnace exhausts, or other sources. Doing so not only conserves resources but also enhances safety conditions around hazardous materials like slag.

Stay Ahead With Cutting-Edge Solutions

As our understanding of sustainable practices deepens, so too does the potential impact of waste heat recovery technologies. Customizing these solutions according to individual business needs ensures optimal performance and long-term profitability. At Sigma Thermal, we pride ourselves on delivering top-tier waste heat recovery systems alongside comprehensive process heating services. From thermal oil heaters to complete automation packages, we cater to diverse client requirements while prioritizing innovation and reliability. To discover how waste heat recovery can benefit YOUR enterprise—or simply inquire further about our offerings—reach out today! We’d love nothing more than helping you turn leftover warmth into tangible gains.

Konica Minolata 1250,Konica Minolata 1050,Refacturing Konica Minolata,Konica Minolata C1085

Guangzhou Baiyin Co.,Ltd , https://www.printerfinisher.com

Leave a Reply Cancel reply