How the Elios 3 Rad Payload is Detecting Radiation Hotspots

Key Benefits at a Glance

| Fast identification and measurement of radiation hotspots using the Elios 3 and new RAD payload. | Safe inspections with no human exposure, enabling scalable operations. | First-time creation of a 3D model of nuclear power plant infrastructure on this site. |

Customer Needs

Elios was recently deployed at a major U.S. nuclear power plant as part of a trial to integrate the RAD payload into existing inspection workflows. The goal was to find an efficient system for locating and measuring radiation hotspots. Plant managers wanted to compare the Elios 3 with the Telepole, a handheld radiation sensor from Mirion that extends up to 11 feet (3.3 meters). Both tools are used to inspect hard-to-reach areas, but the Elios 3 offers a longer range due to its remote operation.

Solution

The Elios 3 was deployed across multiple locations within the plant, equipped with the RAD sensor. The RAD payload uses the RDS-32 WR sensor from Mirion, which sends real-time data back to the pilot. "The addition of radiation detection to the drone allows us to survey dangerous areas without exposing technicians to radiation or industrial hazards," said the ALARA specialist. "It also helps us estimate exposure more accurately, even in areas we haven’t typically inspected before."

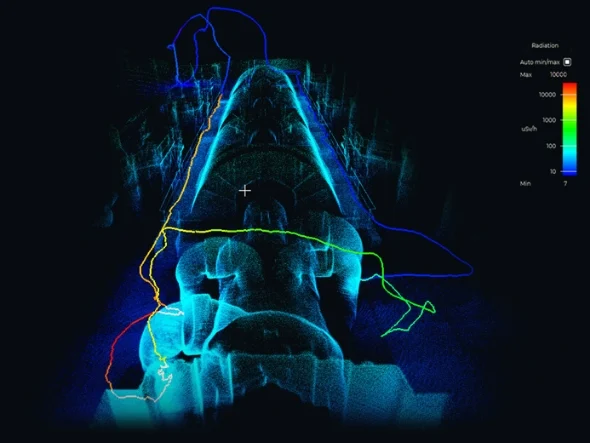

As the pilot received in-flight radiation readings, the team identified spikes indicating hotspots. Two high-dose areas were found in pipe bends, which were flagged for further investigation.

Conclusion

This new radiation inspection workflow proved highly effective, reaching areas that the Telepole couldn't access thanks to the Elios 3's extended range. The collision-resistant design gave pilots confidence to navigate the turbine floor safely. Team members were impressed by the quality and detail of the results. The 3D model created was the first of its kind for a radiation survey, marking a significant advancement in visualizing hotspots. “The drone data is thorough and accurate, giving us confidence that it reflects the actual field conditions,†said the radiation protection technician. Using drones for radiation surveillance reduces unnecessary exposure to both radiation and industrial risks. The parent company is already leveraging drones and robots across their facilities, and the integration of the RAD payload has further enhanced these benefits. With the Elios 3 and RAD payload, accurate, uncrewed radiation surveys are now possible. Given that 80% of U.S. nuclear power plants already use Flyability technology, this workflow is set to expand across the country and beyond.PP-R product line is run Ningbo KonRun Machinery Technology Co., Ltd. developed using the latest technology, high efficiency, reduce production costs. Screw barrel structure of the host unique design, with IKV forced feeding structure and the perfect combination of downstream equipment, so that the entire production line really highly efficient and stable high-speed extrusion line.

Ppr Pipe Extrusion Machine,Ppr Pipe Production Line,Ppr Pipe Extrusion Line,Ppr Pipe Extrusion Making Machine

KonRun Intelligent Machinery(Ningbo) Co., Ltd. , https://www.konrunmachine.com