# Mining Tools – A Comprehensive Guide to Mining Equipment and Machinery

The term "mining tools" broadly encompasses all the equipment and machinery utilized to extract valuable minerals from the Earth. From automobiles to electronics, and even jewelry, minerals mined from the ground play a vital role in nearly every aspect of modern life. Energy sources like uranium and coal, for instance, contribute significantly to the U.S.'s energy supply, accounting for half of its total energy needs.

To successfully extract these resources, a variety of mining tools and equipment are employed depending on the type of mining being performed. Before diving into specific tools, it's important to understand the different methods of mining. This guide begins by outlining the primary mining techniques, followed by a detailed exploration of the tools associated with each method.

## Types of Mining Methods

Mining can be categorized into four main types: underground mining, open-pit (surface) mining, placer mining, and in-situ mining. The choice of mining method depends largely on the type of mineral being extracted and the geological conditions of the site. Regardless of the method, the basic steps of mining involve extraction, material handling, and processing.

### Extraction

This initial step involves physically accessing the minerals through processes like drilling, blasting, or digging.

### Material Handling

Once extracted, minerals are sorted and transported to either a processing facility or a waste area based on their value.

### Processing

Finally, the minerals undergo refinement processes such as crushing, grinding, or smelting to convert them into usable products.

## Surface Mining Methods

Surface mining is ideal for minerals located near the Earth's surface. Common surface mining techniques include:

- **Strip Mining:** This method involves removing layers of topsoil and rock to access minerals beneath, often used for coal extraction.

- **Open-Pit Mining:** This approach uses explosives to create large pits, allowing miners to access deeper mineral deposits.

- **Quarrying:** A process where blocks of hard stone are cut, with by-products like sand or gravel also extracted.

- **In-Situ Leaching (ISL):** Used primarily for uranium extraction, this method dissolves minerals in place without disturbing the surface.

- **Placer Mining:** Utilized for gold extraction, this technique uses water and pans to separate heavier metals from lighter sediments.

*Image: Open-pit mine via Adam Rhodes on Unsplash*

## Underground Mining Methods

For minerals buried deep within the Earth, underground mining becomes necessary. Techniques include:

- **Blast Mining:** Uses explosives to break through hard rock layers.

- **Room and Pillar Mining:** Creates rectangular pillars to support the ceiling while extracting minerals around them.

- **Retreat Mining:** Removes pillars in a strategic manner to recover leftover minerals, though this method poses significant risks.

- **Block Caving:** A large-scale method involving blasting gaps at the base of a rock mass to induce collapse.

- **Cut and Fill Mining:** A smaller-scale method where horizontal slices are mined and backfilled.

- **Longwall Mining:** Commonly used in coal mining, this technique employs a shearer to grind coal from the mine face.

- **Shrinkage Stope Mining:** Used for steep, uniform ore bodies, this method involves blasting and backfilling to maximize efficiency.

- **Sublevel Caving:** Suitable for steeply dipping ore bodies, this method extracts ore from the footwall side to prevent fractures.

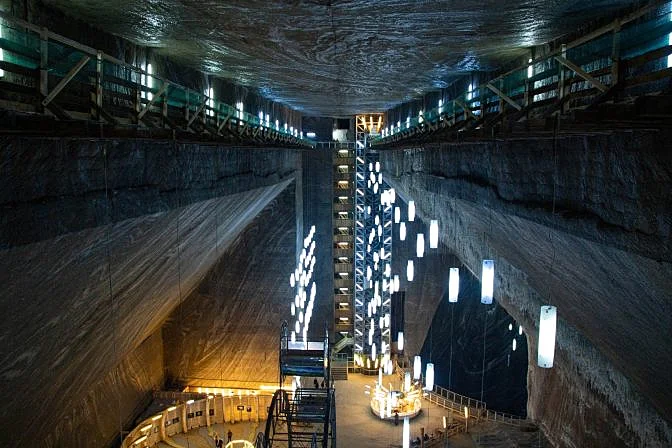

*Image: Salt mine via Szabolcs Molnar from Pixabay*

## Mining Equipment for Soft vs. Hard Rock Mines

The distinction between soft and hard rock mining lies in the tools required. Soft rock mining relies solely on machinery, whereas hard rock mining necessitates the use of explosives.

- **Soft Rock Mines:** Examples include salt, coal, bauxite, and potash. These minerals are typically mined using specialized machinery.

- **Hard Rock Mines:** Minerals such as copper, gold, iron, and uranium require the use of hydraulic drills to create holes for explosives.

## Mining Tools and Equipment

While there are countless mining tools, we’ll categorize them by mining methods for better comprehension. Here's an overview:

- **Miner Tools:** Classic hand tools like pickaxes, hammers, and shovels.

- **Mining PPE:** Personal protective equipment such as respirators, helmets with cap lights, and reflective clothing.

- **Surface Mining Equipment:** Includes blasthole drills, bucket-wheel excavators, dozers, and mining trucks.

- **Underground Mining Equipment:** Features continuous miners, jumbo drills, and shotcrete machines.

## Mining PPE

Safety is paramount in mining operations. Essential PPE includes air respirators, cap lights, hearing protection, miner's belts, and self-rescuers. Reflective clothing ensures visibility, while communication devices enable constant contact.

## Surface Mining Equipment

Surface mining relies heavily on large machinery:

- **Blasthole Drills:** Drill holes for explosives.

- **Bucket-Wheel Excavators:** Continuously dig and transport materials.

- **Dozers:** Move earth across surfaces.

- **Dragline Excavators:** Remove overburden in strip mining.

- **Graders:** Construct roads for hauling minerals.

- **Highwall Miners:** Extract coal from exposed seams.

- **Mining Trucks:** Large vehicles for transporting materials.

- **Shovels:** Used for digging and loading minerals.

- **Wheel Tractor Scrapers:** Load and carry materials.

- **Drones:** Conduct aerial surveys and inspections.

*Image: Blasthole drill via Cat Models*

## Underground Mining Equipment

Underground mining requires specialized equipment:

- **Crane Lifts:** Load heavy materials and equipment.

- **Continuous Miners:** Scrape coal from seams with carbide teeth.

- **Drones:** Inspect dangerous areas like stopes and ore passes.

- **Jumbo Drills:** Drill holes for explosives or mine shafts.

- **Loaders and Haulers:** Compact loaders and haulers for transporting minerals.

- **Longwall Mining Machines:** Build underground galleries.

- **Refuge Chambers:** Emergency shelters for miners.

- **Rock Dusters:** Prevent shaft combustion.

- **Roof Bolters:** Secure mine ceilings.

- **Scoops:** Load minerals onto trucks.

- **Shotcrete Machines:** Reinforce mine tunnels.

- **Underground Rails:** Transport miners and materials.

- **Ventilation Systems:** Provide clean air and regulate temperature.

## Other Mining Tools

Additional tools used in both surface and underground mining include hoppers, conveyors, crushers, and screens. These facilitate the movement and processing of materials.

## Conclusion

The mining industry remains vital, requiring robust and adaptable tools. With advancements in technology, drones and LiDAR scans are transforming safety and efficiency. For example, drones like the Elios 3 provide remote access for inspections, reducing risks and enhancing productivity. While the industry evolves slowly, embracing innovations like drone technology promises safer, faster, and more efficient operations.

*Image: Elios 3 drone via Flyability*

Mining tools continue to evolve, ensuring they remain indispensable in the ever-changing landscape of resource extraction.

Chemicals Used In Galvanizing Process

Chemicals Used In Galvanizing Process,Ammonium Chloride,Sodium hydroxide,Hydrogen peroxide,Ammonia Solution, Zinc chloride

Xinbai Plating(jiangsu) Intelligent Technology Co.,Ltd , https://www.hotgalvanizing.com