When conducting internal inspections, every inspector must answer three key questions to ensure a thorough and effective evaluation of the asset. These questions are not just important—they are essential to the entire inspection process.

The three fundamental questions are:

- Are there any defects in the asset?

- What are the dimensions of the defect(s) found?

- Where are the defects located within the asset?

At Flyability, helping inspectors answer these three critical questions is at the core of everything we do. Since our launch in 2014, these questions have guided our product development and continue to shape our innovation today.

Question 1: Are there any defects in the asset?

The first question—whether or not there are any defects—is often the most basic but also the most crucial. It’s the starting point for all inspections. When we launched Flyability, this was our top priority.

To help inspectors access hard-to-reach areas safely, we developed the Elios, the world's first indoor drone with a protective cage. This allowed inspectors to remotely enter confined spaces and capture visual data without putting themselves at risk.

This breakthrough gave inspectors the ability to see what was inside an asset, making it possible to identify potential issues before they became serious problems.

Question 2: What are the dimensions of the defect?

Once a defect is identified, the next step is to understand its size. This information is vital for maintenance teams to decide on the appropriate course of action—whether to repair, monitor, or conduct further inspections.

That’s why, after launching the Elios, we focused on improving how inspectors could measure and document the size of defects. We worked closely with field professionals to gather insights into their needs and challenges during internal inspections.

[Related read: Elios 2 Tested 15 Times by Ronik Inspectioneering, Approved as a Formal Inspection Tool]

Based on this feedback, we developed the Elios 2, which includes advanced features such as 2D measurements, photogrammetric modeling, improved lighting, and high-resolution imaging. These tools allow inspectors to collect detailed data that helps them accurately assess the size and severity of defects.

These enhancements make it easier than ever for inspectors to collect the precise data needed to make informed decisions about asset condition and maintenance priorities.

Question 3: Where are the defects located in the asset?

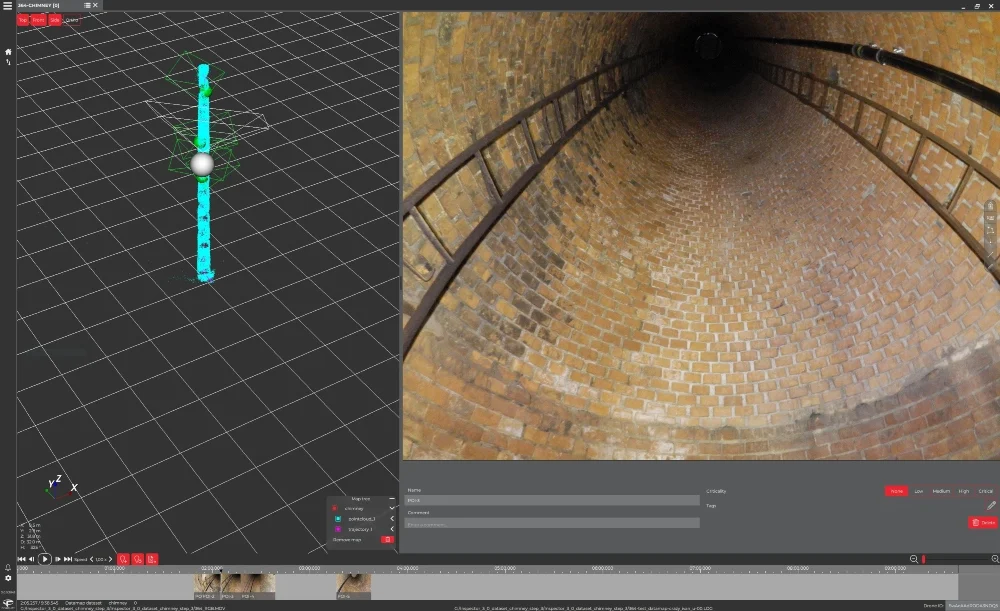

The final and most complex question is determining where exactly the defect is located within the asset. In confined spaces, traditional positioning systems like GPS are unavailable, making it difficult to pinpoint exact locations based solely on video footage.

This challenge is even greater in environments with uniform surfaces, such as tanks or chimneys, where there are no clear reference points. Inspectors often rely on barometric data, maps, blueprints, and approximate timing to estimate locations—a process that can be time-consuming and error-prone.

To address this, we developed Inspector 3.0, a software solution that enables inspectors to quickly generate sparse 3D models of the inspected area. These models provide accurate spatial data, allowing inspectors to locate defects with precision.

With Inspector 3.0, inspectors gain access to usable location data, fast processing times, and intuitive navigation through 3D models. This makes it much easier to track and report on defects during inspections.

[Related read: Inspector 3.0 Helps Save Hours of Work Locating Defects in Hydrogen Reformer Inspection]

Today, we’ve built solutions that help inspectors answer all three questions effectively. But our work doesn’t stop here. We’re always looking for ways to improve data collection, enhance software capabilities, and support inspectors in their daily tasks.

As we continue to innovate, these three questions will remain central to our mission. By focusing on them, we aim to make inspections safer, faster, and more efficient for everyone involved.

PPGI stands for "Pre-Painted Galvanized Iron," a type of steel that’s coated with paint or another protective layer before it’s shaped into products like roofing sheets, wall panels, and corrugated sheets. This pre-painting step enhances the steel’s durability and protects it from corrosion and environmental wear. Its strength, flexibility, and good looks make PPGI a popular choice in the construction world.

The galvanized coating on PPGI shields it from rust and corrosion, which is especially useful in humid areas, coastal environments, or places with industrial pollution.

One of the major perks of PPGI is the variety it offers in colors and finishes. This gives architects and designers the freedom to bring their creative ideas to life when designing roofs or building facades.

It’s also simple to install and doesn’t need much upkeep. Since it’s already painted, there’s no need for additional coatings, which saves both time and money.

Despite being lightweight, PPGI is incredibly strong. This makes it perfect for roofing and cladding projects. On top of that, it can handle impacts well and offers fire resistance, which adds another layer of safety to any structure.

Another bonus? It’s recyclable. The steel can be melted down and reused, which means less waste in landfills and a more sustainable choice for green building efforts.

All in all, PPGI is a reliable, multipurpose material that’s valued in the construction sector for its long-lasting performance, visual appeal, and environmental friendliness.

Related Suggestion: ppgi coil, color coated coil, PPGI STEEL COIL, color coated coil ppgi, ppgi prepainted Galvanized Steel coil, PPGI (Prepainted Steel Coil/Sheet/Strip)

ppgi coil,color coated coil,PPGI STEEL COIL,color coated coil ppgi,ppgi prepainted galvanized steel coil

Wuxi Shengshu Metal Co., Ltd. , https://www.wuxissmetal.com