When conducting internal inspections, there are three key questions that every inspector must answer to ensure a thorough and effective assessment of an asset.

These questions are:

- Are there any defects in the asset?

- What are the dimensions of the defect(s) found?

- Where are the defects located within the asset?

At Flyability, helping inspectors answer these three fundamental questions is at the core of everything we do. Since our launch in 2014, these questions have guided our product development and continue to shape our innovation today. Let’s take a closer look at how we’ve addressed each one.

Question 1: Are there any defects in the asset?

The first and most critical question for any inspector is whether or not a defect exists within the asset. This was our main focus when we launched Flyability. Traditional methods often required inspectors to enter confined or hazardous spaces, which posed significant risks and limitations.

To solve this, we developed the Elios drone—a compact, caged drone designed specifically for indoor use. The Elios allows inspectors to safely enter hard-to-reach areas and collect visual data remotely, giving them the ability to identify potential issues without physical exposure.

This breakthrough allowed inspectors to see what was previously out of reach, making safety and efficiency central to the inspection process.

Question 2: What are the dimensions of the defect?

Once a defect is identified, the next step is understanding its size and severity. This information is crucial for maintenance teams to decide on the appropriate course of action—whether to repair, monitor, or conduct further inspections.

After launching the Elios, we focused on improving the data inspectors could collect to better understand defect dimensions. We worked closely with field professionals, gathering feedback and refining our technology to meet real-world needs.

The result was the Elios 2, an upgraded version that offers advanced features such as 2D measurements, photogrammetric modeling, improved lighting, and 4K video capture. These tools help inspectors get precise data about the size and structure of defects, enabling more informed decision-making.

With these enhancements, the Elios 2 has become a powerful tool for detailed and accurate defect analysis.

Question 3: Where are the defects located in the asset?

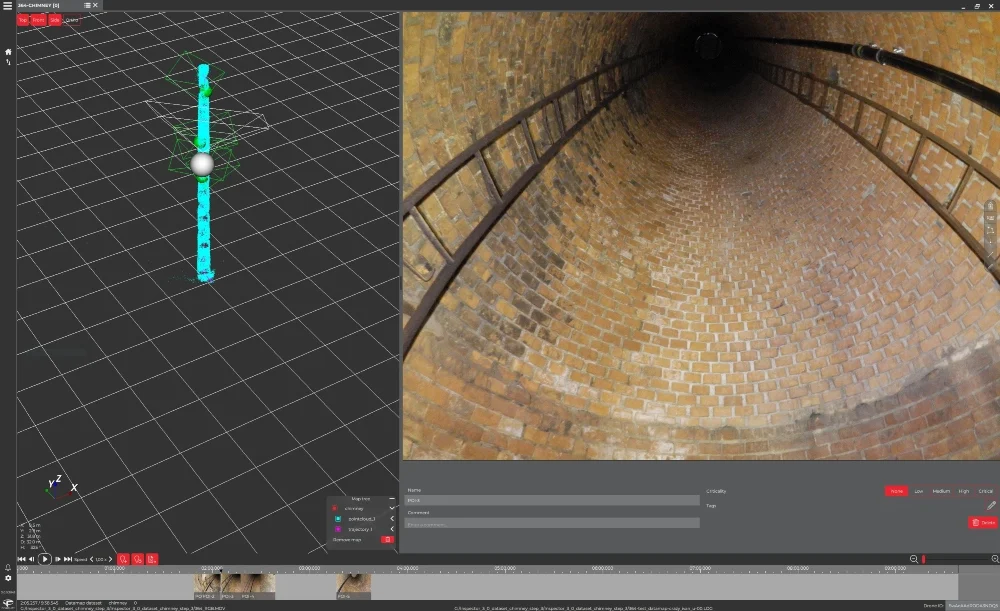

The third question—determining the exact location of a defect—is often the most challenging, especially in confined or featureless environments like tanks or chimneys. Without reliable indoor positioning systems, it can be difficult for inspectors to pinpoint where a defect is located based solely on video footage.

That’s why we developed Inspector 3.0, a software solution that helps inspectors create 3D models of the inspected area. These models provide clear, spatially accurate representations of defects, making it easy to locate and reference them during analysis.

Inspector 3.0 offers several benefits, including quick model generation, easy data integration, and intuitive navigation through Points of Interest (POIs). This makes it significantly easier for inspectors to track and report on defects accurately.

With the release of Inspector 3.0, we now offer a complete solution for answering all three essential questions inspectors face during internal inspections.

But our work doesn’t stop here. We’re continuously exploring new ways to enhance our technology and improve the data inspectors can access. As we develop new drones and software, these three questions will remain at the heart of our mission—ensuring that our tools help inspectors work faster, safer, and more effectively in even the most challenging environments.

Flower pattern steel coil, also known as floral pattern steel coil or decorative pattern steel coil, refers to a type of steel coil that features an embossed or printed pattern resembling flowers or floral designs on its surface. It is primarily used for decorative purposes in various industries, including construction, automotive, and interior design.

The manufacturing process for flower pattern steel coil involves embossing or printing the desired floral pattern onto the surface of the steel coil. This can be achieved through various methods, such as hot embossing, cold embossing, or printing with specialized equipment. The pattern is typically created using high-quality paints or coatings that are resistant to fading, corrosion, and wear.

The floral pattern on the steel coil adds aesthetic appeal and uniqueness to the finished products made from it. It is often used in applications such as wall cladding, roofing, decorative panels, furniture, and appliances. The coil's patterned surface can enhance the visual appeal of these products, making them stand out and adding a touch of elegance to the overall design.

Flower pattern steel coil is available in different colors, sizes, and patterns, allowing for customization to suit specific design requirements. Manufacturers often offer a wide range of floral patterns to choose from, giving customers the flexibility to select the desired design that aligns with their aesthetic preferences.

precoated metal with flower pattern,ppgi flower,flower steel coil,flower printed steel coil

Wuxi Shengshu Metal Co., Ltd. , https://www.wuxissmetal.com